Have you noticed how cars today are packed with safety features? Older vehicles lacked basic protections we now take for granted. Dangerous designs once lurked beneath stylish exteriors, putting drivers at serious risk. Sharp metal, poor restraints, and weak structures turned minor crashes into deadly accidents.

Our cars have become dramatically safer through decades of tough lessons.

19. Propeller-Driven Cars: A Risky Dream

The ambitious yet dangerous experiment of propeller-driven cars emerged during the early 20th century automotive innovation boom. Enthusiastic engineers attached aircraft-style propellers to vehicles with hopes of surpassing conventional engine speeds and efficiency. These experimental machines generated tremendous thrust but simultaneously created lethal risks for pedestrians, cyclists, and nearby motorists. From considerable distances, you could hear the distinctive roaring sounds of these unusual vehicles announcing their presence unlike any traditional automobile. Most propeller cars could reach speeds of 70+ mph when conventional vehicles struggled to maintain half that velocity—a thrilling but ultimately deadly technological dead-end that sacrificed safety for spectacle.

18. Water Balloon Bumpers: A Failed Innovation

During the experimental automotive safety period of the 1960s, water balloon bumpers briefly appeared as a novel concept. Designers conceived these unusual safety features as inflatable water-filled membranes meant to absorb collision energy. Theoretically, these systems would distribute crash forces while providing a softer impact surface than conventional bumpers. Real-world testing revealed catastrophic flaws when punctures caused immediate deflation or freezing temperatures rendered the systems solid and ineffective. Only 3 prototype models ever incorporated this technology before researchers abandoned the concept entirely. Each prototype required 15 gallons of water to function—imagine having to top up your bumpers alongside your windshield washer fluid!

17. Non-Collapsible Steering Columns: A Major Hazard

Among the deadliest features in pre-1967 automobiles, non-collapsible steering columns caused thousands of preventable fatalities. Automotive engineers constructed these rigid metal shafts connecting the steering wheel directly to the vehicle’s front axle without any collapsible sections. Frontal collisions frequently resulted in drivers being impaled as their bodies continued forward while the steering wheel remained fixed in position. Safety advocate Ralph Nader’s influential book “Unsafe at Any Speed” finally brought widespread attention to this long-ignored danger. Post-regulation accident data showed a 28% reduction in fatal chest injuries after collapsible columns became standard—a silent lifesaver that now protects every driver on today’s roads.

16. Swingaway Steering Wheels: A Risky Convenience

Ford’s introduction of swingaway steering wheels in the 1960s represented a popular convenience feature in larger American automobiles. The innovative mechanism allowed the entire steering wheel to move horizontally away from the driver’s position, facilitating easier vehicle entry and exit. Through a hinge mechanism, the steering wheel swung rightward when the transmission entered park position. Convenience came with considerable risk, as these mechanisms often failed during accidents, creating unpredictable movement during crashes. Ford installed these systems in over 500,000 vehicles between 1961 and 1969, primarily in luxury models like the Thunderbird and higher-trim Galaxies—a perfect example of how yesterday’s luxury feature often becomes tomorrow’s safety liability.

15. Wrist Twist Swivel System: An Unconventional Approach

General Motors’ experimental Wrist Twist steering system ranks among the most unusual control systems developed during the 1960s. This radical design replaced conventional steering wheels with two small 5-inch diameter wheels mounted horizontally, designed for operation using only wrist movements. Engineers created the system to minimize driver fatigue and enhance dashboard instrument visibility. During practical testing, the counterintuitive controls proved dangerously ineffective as drivers struggled with vehicle control during emergency maneuvers. GM allocated $1.2 million to development before abandoning the project after 97% of test subjects rejected the concept—proof that even the biggest automakers occasionally pursue ideas so bizarre they make you wonder what they were thinking.

14. Lack of Headrests: A Common Oversight

Before 1969, the absence of headrests in automobiles created a significant yet overlooked risk for whiplash injuries during rear-end collisions. Standard vehicles featured bench or bucket seats with low seatbacks that provided no protection for occupants’ necks and heads during impacts. Rear-end collisions caused violent backward head movements as vehicles suddenly accelerated forward, resulting in serious neck injuries even during minor accidents. Medical research identified that without proper head support, occupants experienced neck strain forces up to 5 times greater than in vehicles equipped with headrests. Early insurance industry data indicated whiplash claims decreased by 32% in the first year after headrests became mandatory—transforming what was once considered a minor “luxury feature” into an essential safety component no manufacturer would dare omit today.

13. Dangerous Hood Ornaments: More Hazardous Than Stylish

Throughout much of the 20th century, decorative hood ornaments adorned luxury and premium vehicles as brand symbols and artistic expressions. Solid metal construction created rigid projections extending several inches from the vehicle’s front end, significantly increasing injury severity during pedestrian impacts. Premium vehicle identification often came through these distinctive hood emblems – Mercedes-Benz’s standing star, Jaguar’s leaping cat figure, and various other manufacturer-specific designs. Pedestrian safety research eventually documented the substantial increase in laceration risks when these ornaments struck pedestrians. European regulators found that hood ornaments increased pedestrian injury severity by 26% in low-speed impacts—forcing a redesign that transformed these status symbols from deadly projections into collapsible decorations that fold away on impact.

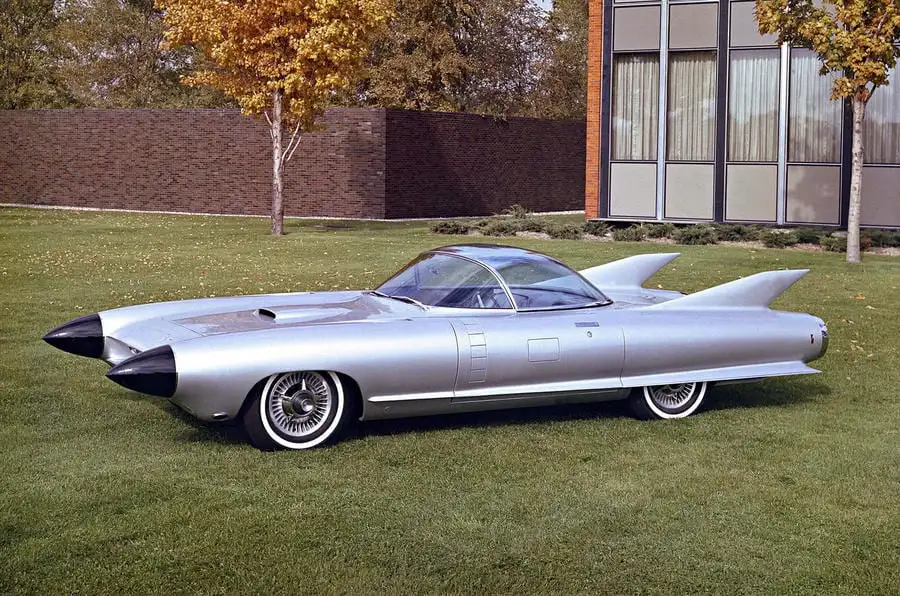

12. Jet Age Design Elements: Aesthetic Risks

American automobiles underwent dramatic transformation during the 1950s as manufacturers embraced aviation-inspired styling in their designs. Sharp tail fins, protruding chrome bumpers, and pointed projections mimicking contemporary aircraft aesthetics became hallmarks of this design era. Pedestrian and cyclist safety suffered significantly from these dramatic styling features, which created numerous hazards including severe laceration and puncture wound risks. Manufacturers produced over 7.5 million vehicles with these dangerous design elements before safety concerns gradually shifted aesthetic priorities. The infamous 1959 Cadillac featured tail fins measuring a record 11 inches high with points sharp enough to puncture thin sheet metal—making it perhaps the only production car in history that could literally stab another vehicle during a minor fender bender.

11. Bench Seats: Comfort with Safety Drawbacks

For decades, bench seats dominated automotive interiors, providing spacious seating across the entire width of vehicle cabins. These wide, uninterrupted seating surfaces accommodated three front passengers comfortably and became synonymous with American car design through the 1970s. If you’ve ever slid across a vinyl bench seat during a sharp turn, you’ve experienced firsthand the safety compromises these seats created during emergency maneuvers. Lateral support deficiencies meant occupants had minimal protection against side forces during collisions or sharp turns. Crash test data eventually showed that during a 30 mph side impact, unbelted passengers on bench seats moved laterally at speeds approaching 20 mph before striking doors or other occupants—an internal collision nearly as dangerous as the external one that caused it.

10. Rigid Steering Wheels: A Dangerous Standard

Before the 1960s, rigid steering wheels presented serious injury risks to drivers during frontal collisions. Manufacturers built these components with solid metal rings and spokes without energy-absorbing features, essentially placing rigid obstacles directly before drivers. Crash investigations documented severe chest trauma patterns as drivers impacted these unyielding structures. Worst designs incorporated pointed metal horn rings at the center and sharp-edged spokes that caused additional injuries upon impact. Data collected from real-world accidents showed that chest injuries decreased by 73% after energy-absorbing steering wheels became standard equipment, saving an estimated 1,300 lives annually in the United States alone—a remarkable improvement achieved through a design change nearly invisible to the average driver but felt dramatically in those crucial milliseconds of impact.

9. T-Top Roofs: Stylish but Risky

The 1970s saw widespread adoption of T-top roofs as an open-air alternative that promised to maintain most of a vehicle’s structural rigidity. Distinctive in design, these roof systems featured removable panels on either side of a central support bar, offering partial convertible benefits without completely eliminating structural support. Structural engineering analyses revealed serious safety compromises through weakened overall rigidity and minimal rollover protection compared to solid-roof vehicles. NHTSA data showed vehicles with T-tops had 46% less roof crush resistance during rollovers compared to hardtop versions of the same models. The 1968 Corvette became the first production car with factory T-tops, with over 25,000 units sold in the first year—proving once again that Americans will gladly trade safety for style when the compromise isn’t immediately obvious.

8. Asbestos Brake Pads: Health Hazards

For decades, asbestos brake pads dominated automotive braking systems before medical research fully documented their severe health risks. Manufacturing preferences favored asbestos for its exceptional heat resistance and friction properties, making it seemingly ideal for demanding vehicle braking applications. Normal wear released microscopic fibers that mechanics and nearby pedestrians unknowingly inhaled, resulting in serious respiratory diseases. If you’ve ever wondered why older mechanics are so cautious around brake dust, this deadly history explains their caution. Medical studies confirmed that workers regularly exposed to brake dust faced 5 times higher risk of developing asbestos-related diseases compared to the general population. A single brake job released approximately 16 million asbestos fibers per cubic meter of air—a silent, invisible killer that claimed thousands of lives long after the vehicles themselves had rusted away.

7. Early Airbag Deployment: A Double-Edged Sword

First-generation airbag deployment systems introduced in the 1970s and 1980s represented significant safety advancements despite serious shortcomings. These early systems deployed with excessive force – up to 200 mph – causing serious injuries to smaller drivers and passengers seated too close to the dashboard. Technical limitations meant these systems lacked sophisticated sensors to modulate deployment force based on crash severity or occupant position, resulting in an all-or-nothing approach. Injury data showed children and petite adults suffered disproportionate injuries from these powerful deployments, including facial fractures and neck trauma. Between 1990 and 1996, first-generation airbags saved an estimated 1,300 lives but caused 68 deaths—a stark reminder that safety innovations often come with unintended consequences that only real-world deployment can reveal.

6. Poor Door Latches: A Safety Concern

Vehicle ejection risks increased significantly due to poor door latches in vintage vehicles during accidents and rollovers. Simple mechanical latches without secondary safety catches characterized early automotive door mechanisms, allowing doors to spring open during side impacts or vehicle rollovers. Accident investigations documented how these inadequate retention systems contributed to thousands of preventable fatalities as occupants ejected from vehicles during crashes. That satisfying “thunk” you hear when closing a modern car door isn’t just about perceived quality—it’s the sound of multiple redundant safety systems engaging. NHTSA data showed ejection increased death risk by over 300% compared to remaining inside during crashes. Ford’s infamous 1970s door latch design required just 15 pounds of force to fail during side impacts—barely more than the force needed to close the door normally, yet enough to turn a survivable accident into a fatal ejection.

5. Drum Brakes: An Outdated Technology

Standard equipment on most vehicles until the 1970s, drum brakes presented serious performance limitations despite widespread use. Engineering designs enclosed friction materials within drums attached to wheels, providing effective stopping power under ideal conditions. Heat management problems became apparent during repeated stops as the enclosed design trapped heat, causing brake fade that dramatically reduced stopping performance—a terrifying experience if you’ve ever descended a mountain in a vintage car. Performance testing showed that after just 5 consecutive hard stops from 60 mph, typical drum brakes lost over 70% of their effectiveness. The 1965 Chevrolet Corvette became the first American production car with four-wheel disc brakes—pioneering a technology that didn’t just stop cars better but fundamentally transformed what drivers could expect from their vehicles in emergency situations.

4. Pop-Out Windshields: A Risky Feature

Early automobiles often featured pop-out windshields serving as both design elements and primitive safety systems. Engineering specifications called for relatively weak seals designed to allow entire windshields to separate during accidents, theoretically reducing injuries from broken glass. Historical accident reports show this approach frequently backfired when windshields ejected during minor collisions or even during regular driving over rough roads. Safety analyses documented how the large separated glass panels often caused additional injuries to pedestrians or vehicle occupants. Pre-1953 vehicles used installation methods that failed with as little as 80 pounds of pressure—creating the bizarre scenario where a windshield designed to “safely” eject during an accident might do so simply because you hit a pothole while driving down a bumpy road.

3. Only Lap Waist Seat Belts: Limited Protection

Vehicles manufactured before the late 1960s typically provided only lap waist seat belts with minimal occupant protection effectiveness. Simple in design, these restraints secured only the occupant’s lower body while leaving the upper torso completely unrestrained during collisions. Crash investigation data showed that during frontal impacts, passengers experienced severe “jackknife” motions as their upper bodies continued forward while their hips remained relatively secured. Medical records documented how this partial restraint often caused serious abdominal injuries and facial trauma as occupants struck interior components. Statistical analysis confirms that three-point seat belts reduce fatality risk by approximately 50% compared to lap belts alone. Early lap belt-only systems decreased fatalities by just 17% compared to no restraints—making them perhaps the most dramatic example of how a half-measure in safety design can create a false sense of security while leaving critical vulnerabilities unaddressed. Speaking of cars in the 1960s, here are 20 of the ugliest from that time.

2. Absence of Crumple Zones: A Major Safety Flaw

Before the 1970s, most vehicles lacked crumple zones, resulting in catastrophic energy transfer to occupants during collisions. Engineering philosophy prioritized rigid construction, viewing structural deformation as a design failure rather than a safety feature. Physical analysis demonstrates how these stiff structures transmitted crash forces directly to the passenger compartment instead of absorbing and dissipating energy through controlled deformation. That vintage car you admire for being “built like a tank” actually represents a fundamentally flawed safety approach, with rigidity that endangered occupants rather than protected them. Modern crash tests comparing 1959 and 2009 models of the same vehicle showed the driver in the vintage car would experience forces 30 times greater than in the modern vehicle—transforming what might be a walk-away accident in today’s cars into a fatal collision in their stylish but lethal predecessors.

1. Unsafe Fuel Tanks: A Notorious Example

Catastrophic fire risks emerged from unsafe fuel tanks in numerous vintage vehicles, with the Ford Pinto becoming the most infamous historical case. Engineering decisions positioned the Pinto’s fuel tank behind the rear axle with minimal protection from rear-end collisions. Accident investigations documented how sharp bolts and brackets surrounding the tank could puncture it during impacts as mild as 20 mph, releasing highly flammable gasoline near potential ignition sources. Court proceedings revealed internal company documents calculating that paying settlements for burn injuries and deaths would cost less than modifying the design. Ford’s own risk analysis valued each human life at just $200,000 while estimating the safety modification would cost $11 per vehicle—a coldly calculated decision that ultimately cost far more in human suffering, legal settlements, and corporate reputation than the simple fix would have cost to implement.