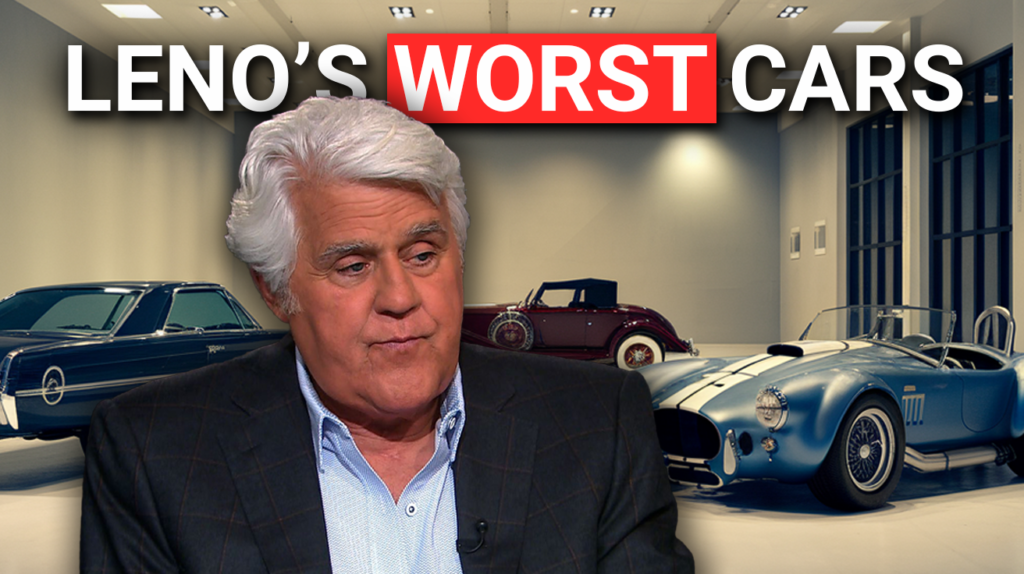

America’s automotive history brims with legendary successes and notorious flops. Certain vehicles, despite initial hype, ended up parked in infamy. These models stand as testaments to ambitious designs or missed opportunities. Jay Leno, a renowned car enthusiast, owns many unique cars – including some that you could call a “miss” because they were too far ahead of their time, too expensive, too impractical – or some mixture of the three!

10. 1963 Chrysler Turbine (Exterior)

Chrysler’s turbine-powered experiment burned through development money at an alarming rate, becoming too costly to ever reach production. Its regenerative gas turbine produced 130 hp and 425 lb-ft of torque, but came with prohibitive manufacturing expenses that made commercial viability impossible. Chrysler limited production to just 55 examples, each with an exorbitantly expensive Ghia-designed body. The technology proved decades ahead of practical implementation, with the turbine idling at 22,000 RPM and consuming fuel at an economically unsustainable 14-18 mpg. Environmental regulations ultimately killed any production hopes, as nitrogen oxide emissions exceeded increasingly strict standards. The turbine’s significant acceleration lag represented another insurmountable practical hurdle for everyday driving scenarios.

1963 Chrysler Turbine (Interior)

Inside, the 1963 Chrysler Turbine had a conventional cabin that masked the financial black hole beneath the hood. Despite its future-focused powertrain, Chrysler couldn’t justify the astronomical costs of developing unique interior technology to match. The modified TorqueFlite transmission required expensive custom engineering that couldn’t be amortized across normal production volumes. While the engine could burn gasoline, diesel, kerosene, and even tequila, this flexibility proved pointless given the car’s economic impracticality. The complete disconnection between manufacturing expenses and potential pricing became obvious when calculating production costs. No consumer would pay the necessary premium for a vehicle that delivered worse economy and drivability than conventional alternatives, making the program financially unsustainable regardless of its technical merits.

9. 1989 Ford Festiva SHOgun (Exterior)

Ford’s impractical experiment shoehorned a Taurus SHO’s engine into a Festiva’s tiny body at a cost that made production financially impossible. The 140-inch long subcompact housed a wildly expensive 220 horsepower engine that required custom mounting solutions costing more than the base vehicle itself. Widened fenders and 225/50VR-15 tires necessitated handmade body modifications that couldn’t be mass-produced at reasonable costs. The custom driveline alone exceeded the price of an entire standard Festiva. After building just seven examples at astronomical expense, Ford abandoned the financially reckless project. Despite impressive 0-60 mph in 5.4 seconds performance, the SHOgun’s complete lack of practicality and impossible pricing structure relegated it to concept car status.

1989 Ford Festiva SHOgun (Interior)

Severely compromised describes the SHOgun’s restrictive cockpit, which prioritized performance metrics over comfort or practicality. Firm racing bucket seats dominated the confined space, becoming uncomfortable during drives exceeding 30 minutes. The manual shifter required precise inputs while custom gauges proved difficult to monitor at speed. Engineers eliminated rear seats entirely to accommodate the powertrain, removing any pretense of practicality. Excessive heat continuously intruded from the mid-mounted engine, creating an uncomfortably warm environment during normal operation. Noise levels inside the cabin reached disruptive levels at higher RPMs, making conversation difficult and contributing to driver fatigue. The car’s ergonomics reflected its prototype status.

8. 1966 Chevrolet Yenko Stinger Stage 2 (Exterior)

Don Yenko’s performance modifications extracted 240 horsepower from the Corvair’s inherently challenging flat-six engine layout. Stage 2 Stingers received complex four-carburetor setups requiring frequent adjustment, paired with special cylinder heads prone to heat issues. The distinctive racing stripes couldn’t address the car’s fundamental handling limitations inherited from the standard Corvair platform. Unpredictable handling characteristics created genuine challenges for average drivers, particularly during emergency maneuvers or adverse weather conditions. Ralph Nader’s safety criticisms of the Corvair platform proved especially problematic for the Stinger, which amplified the standard car’s handling quirks while adding substantially more power.

1966 Chevrolet Yenko Stinger Stage 2 (Interior)

Minimal comfort defined the Stinger’s interior, with performance considerations taking precedence over daily usability. Firm racing bucket seats replaced the standard Corvair furniture, creating driver fatigue during longer journeys. The wood-rimmed steering wheel provided limited grip when attempting to correct the car’s tendency toward oversteer. Competition versions eliminated rear seats entirely, severely limiting practicality. Additional gauges mounted on the dashboard required driver attention away from the road to monitor critical engine parameters. Considerable heat transferred into the cabin from the rear-mounted engine during spirited driving. Higher than normal noise levels made extended drives tiring and conversation difficult at highway speeds.

7. 1953 Cunningham C3 (Exterior)

Briggs Cunningham’s racing-inspired road car combined American power with Italian styling at a cost that ensured commercial failure. Each vehicle paired a 331-cubic-inch Chrysler Hemi V8 with a hand-formed Vignale body that proved challenging to repair when damaged. Production reached just 25 examples due to unsustainable manufacturing costs. While performance figures of 0-60 mph in 7 seconds and a 150 mph top speed were impressive for 1953, the car’s handling couldn’t match contemporary European sports cars. Body panel consistency varied between examples, with fit and finish issues that shouldn’t have existed at the price point. Complex construction methods meant owners faced significant maintenance challenges requiring specialized knowledge that became increasingly scarce.

1953 Cunningham C3 (Interior)

Premium materials throughout the C3’s cabin failed to justify its extraordinary price tag—equivalent to four Cadillacs when new. Leather surfaces showed premature wear under normal use, while elegant instrumentation sometimes provided inconsistent readings. The large steering wheel lacked power assistance, requiring substantial effort for parking maneuvers. Inadequate ventilation created uncomfortable conditions during warmer weather as heat radiated from the transmission tunnel. Limited seat adjustment options created ergonomic compromises for drivers of varying heights. The cabin’s dimensions meant occupants sat closer together than ideal, while headroom proved insufficient for taller individuals despite the car’s luxury positioning.

6. 1934 Duesenberg Walker Coupe (Exterior)

The one-off Walker Coupe exemplifies Depression-era financial excess with an astronomical price of $25,000 when the average American home cost approximately $3,000. Its supercharged straight-eight produced 320 horsepower that no road infrastructure of the period could utilize effectively, making it impractically powerful for its era. Walker’s coachbuilt body required hundreds of hours of hand-formed metalwork at a time when machine stamping had made mass production far more economical. Weighing over 5,500 pounds, the car’s fuel consumption strained even wealthy owners’ budgets. The entire concept represented technology searching for a nonexistent market—too expensive for all but the wealthiest buyers during economic collapse, yet too impractical to justify even on those terms.

1934 Duesenberg Walker Coupe (Interior)

Economic impracticality extended throughout the cabin, with hand-crafted interior components requiring skilled artisans whose labor costs alone would fund several conventional vehicles. The exotic woods, hand-tooled leather, and custom instrumentation created an interior that cost more than most Americans’ annual salary yet offered comfort no better than cars costing a tenth as much. The oversized steering wheel lacked the power assistance that should have accompanied such premium pricing. The car embodied the market disconnect that eventually bankrupted Duesenberg—creating vehicles so expensive that the potential buyer pool numbered in the dozens worldwide, with each requiring cost-prohibitive custom work. The maintenance requirements exceeded what even most wealthy owners could justify, with specialized knowledge becoming increasingly scarce and expensive.

5. 1962 427 Shelby Cobra (Exterior)

Shelby created the ultimate impractical performance car by installing Ford’s expensive 427 V8 racing engine into a chassis never designed for such power, creating a vehicle with virtually no practical applications. The lightweight 2,300 pound body couldn’t accommodate basic amenities expected by American consumers, yet cost more than many luxury cars of the period. While 0-60 mph in 4.2 seconds impressed on paper, this performance came with ownership costs that exceeded exotic European sports cars without their refinement or prestige. The complete absence of weather protection, safety equipment, or creature comforts limited usability to perfect conditions—impractical even in California where many were sold. The chassis modifications required to handle the power added substantially to manufacturing costs while compromising daily drivability.

1962 427 Shelby Cobra (Interior)

Financial impracticality continued inside the Cobra, where premium pricing delivered an interior less comfortable than cars costing a quarter as much. Basic bucket seats provided minimal support despite the vehicle’s premium positioning in the market. The complete lack of weather protection meant owners required additional vehicles for anything but fair-weather driving, effectively doubling the transportation cost. Excessive noise levels made highway travel unpleasant, while the absence of basic comfort features made longer journeys physically taxing despite the high purchase price. Heat from both transmission and engine created cabin temperatures that limited usability in warmer climates. The Cobra embodied the definition of an expensive toy rather than practical transportation, with ownership costs that could never be justified on any practical basis.

4. 1941 American LaFrance Series 600 Pumper V12 Fire Truck (Exterior)

Practical limitations make private ownership of this retired municipal vehicle financially unjustifiable despite its historical significance. The American LaFrance Series 600 requires dedicated commercial storage space costing thousands annually, as its dimensions exceed what any residential garage can accommodate. Operating costs start with the V12 engine’s prodigious fuel consumption, which can exceed 5-7 mpg under normal conditions. Insurance costs reflect commercial vehicle rates rather than standard collector policies, adding thousands to annual ownership expenses. Transportation for service requires specialized equipment costing hundreds per hour. Most components require custom fabrication when they fail, with original parts stocks depleted decades ago. The turning radius exceeds what most residential streets can accommodate, limiting where the vehicle can practically operate.

1941 American LaFrance Series 600 Pumper V12 Fire Truck (Interior)

Financial practicality disappears entirely when considering restoration and maintenance costs for the LaFrance’s utilitarian cabin. Basic comfort upgrades to make operation tolerable add thousands to an already expensive proposition. The oversized controls require periodic maintenance by specialists familiar with heavy equipment of the era, commanding premium hourly rates. Climate control remains effectively nonexistent, limiting practical use to narrow temperature ranges. Restoration of the complex mechanical controls that operate firefighting equipment serves no practical purpose yet costs tens of thousands to maintain for historical accuracy. The specialized knowledge required for proper maintenance grows scarcer each year, with the remaining experts commanding rates that make routine service economically punishing for private owners.

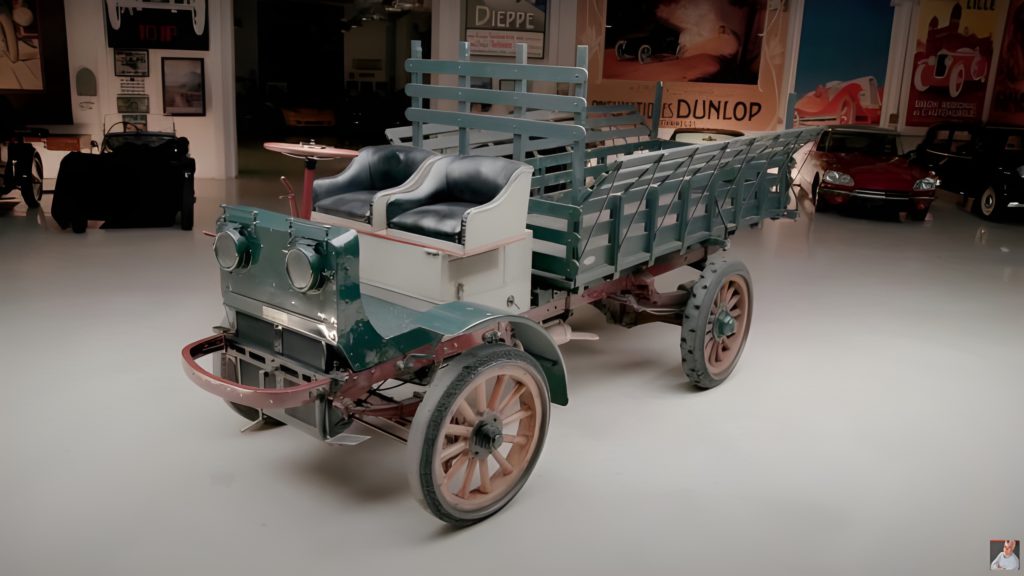

3. 1916 Autocar (Exterior)

Historical significance can’t overcome the financial burden of maintaining this century-old commercial truck. The 1916 Autocar’s primitive twin-cylinder engine requires specialized knowledge increasingly difficult to find at any price. Solid rubber tires must be custom manufactured at extraordinary cost, with each set representing a significant percentage of the vehicle’s total value. Transportation to specialized service facilities adds thousands to routine maintenance costs. Operating limitations restrict the vehicle to roads that no longer exist in most areas, requiring trailer transport to suitable demonstration locations. The complete absence of weather protection means operation is limited to fair weather, reducing usability to a handful of days annually in most regions. Storage requirements add thousands in annual overhead before a wheel turns.

1916 Autocar (Interior)

Economic challenges continue in the operator’s area, which requires significant investment to maintain yet offers comfort worse than a modern garden tractor. The hard metal seating surface necessitates custom cushions for anything beyond brief operation. Exposure to elements means interior components suffer accelerated degradation requiring frequent restoration at specialist rates. Control mechanisms feature materials and manufacturing techniques no longer in common use, requiring custom fabrication for replacements. The primitive mechanical systems demand expertise vanishingly rare in the modern era, commanding hourly rates that make routine maintenance financially punishing. The vehicle represents the definition of an expensive museum piece rather than practical transportation, with operating costs that can never be justified on any utilitarian basis, and car features that have been long replaced.

2. 1957 Buick Roadmaster (Exterior)

Size and inefficiency make the Roadmaster increasingly impractical in the modern era despite its historical appeal. The 364 cubic inch V8 engine delivers fuel economy of just 10-12 mpg using modern gasoline that costs 15 times what it did when the car was new. The excessive length—over 214 inches—exceeds many modern parking spaces, limiting where the vehicle can practically be used. Restoration costs have skyrocketed as specialized chrome plating and stainless steel polishing techniques command premium pricing that can exceed $20,000 for exterior brightwork alone. Rust remediation typically starts at $15,000 for minimal work, with comprehensive restoration easily exceeding the car’s market value. The 4,400 pound weight necessitates brake system upgrades for safety, adding thousands to maintenance costs while reducing originality.

1957 Buick Roadmaster (Interior)

Financial realities continue inside, where restoration costs for period-correct materials exceed what many owners can justify. Proper upholstery work using authentic materials starts at $8,000-$10,000 for basic refurbishment. The complex power accessories—windows, seats, and accessories—feature motors and switches no longer manufactured, requiring expensive rebuilding of original components. Climate control systems demand complete reengineering to function effectively with modern refrigerants, adding thousands to operating costs. Dashboard restoration routinely exceeds $5,000 due to the specialized materials and techniques required. The economics of maintaining a Roadmaster to original standards rarely make financial sense, with most examples receiving compromised restorations that limit both authenticity and value.

1. 1918 Cadillac Type 57 Victoria (Exterior)

Pioneering technology comes with prohibitive maintenance costs that make the Type 57 economically challenging to preserve. Though historically significant as one of the first mass-produced vehicles with a V8 engine (displacing 314 cubic inches), this early powerplant requires specialized machining no longer common in the industry. Maintaining the distinctive V-shaped radiator demands custom fabrication costing thousands when repairs become necessary. Body panels, when damaged, require hand-forming by metal craftspeople commanding upwards of $100 per hour. The primitive electrical system must be completely replaced to achieve reliable operation, yet doing so reduces authenticity and value. Specialized knowledge required for proper maintenance grows increasingly rare, with the few remaining experts charging rates that make routine service financially punishing.

1918 Cadillac Type 57 Victoria (Interior)

Financial impracticality extends throughout the cabin, where restoration using period-correct materials can easily exceed the vehicle’s market value. Authentic upholstery materials must be specially sourced and installed by craftspeople specializing in century-old techniques. The instrument panel requires specialized restoration by experts familiar with early automotive gauges, with costs starting at several thousand dollars. Interior wood components demand attention from furniture-grade restorers charging premium rates for their specialized knowledge. Climate control remains non-existent, limiting practical use to narrow temperature ranges. The economics of maintaining a Type 57 to original standards rarely make financial sense, with most examples receiving compromised restorations that satisfy neither authenticity nor modern usability requirements.